In the evolving world of construction, speed, efficiency, and cost-effectiveness are crucial. PEB (Pre-Engineered Building) systems have emerged as a modern solution that addresses these challenges across industrial, commercial, and institutional projects. Built with factory-fabricated components and assembled on-site, Pre-Engineered Buildings are transforming the way we build.

A Pre-Engineered Building (PEB) is a structural system designed and manufactured off-site and then assembled at the construction location. It consists of pre-fabricated components, including primary and secondary structural members, roofing, wall panels, and other accessories, engineered for rapid construction and cost efficiency.

Pre-Engineered Building (PEB)

A Pre-Engineered Building (PEB) is a type of construction system where the structural components are engineered, designed, and manufactured at a factory, and then transported to the construction site for quick assembly. These systems include:

- Primary structural members (columns and rafters)

- Secondary structural components (purlins, girts, bracing)

- Roof and wall panels

- Fasteners, trims, and accessories

Each element is precisely fabricated and quality-tested before reaching the site, ensuring consistency and reducing the risk of delays and errors.

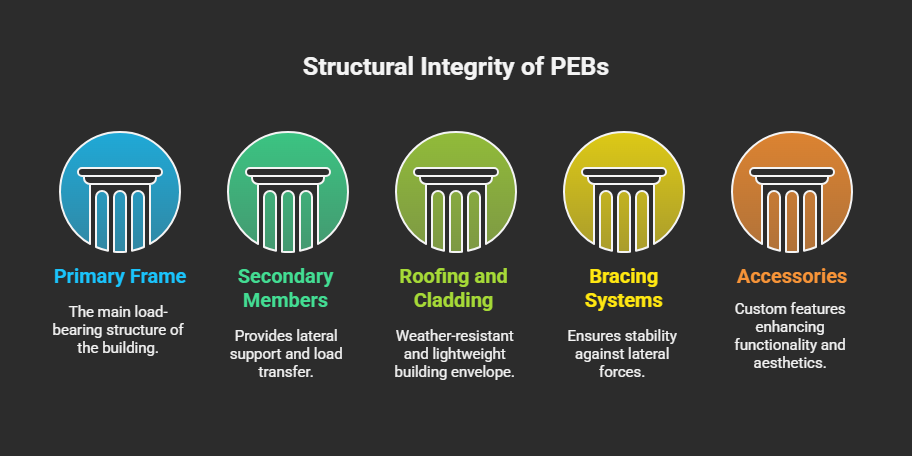

Key Components of a Pre-Engineered Building (PEB)

Understanding the core elements of a Pre-Engineered Building helps appreciate its engineering precision and performance. Below are the five primary components of a PEB, each playing a vital role in its structural integrity and functionality.

1. Primary Frame

The primary frame is the backbone of a PEB structure. It is constructed using I-beams or tapered built-up sections, which are specially engineered to carry the entire building’s vertical and horizontal loads. These include dead loads (weight of the structure itself), live loads (occupants, equipment), and environmental forces like wind and snow.

Each element—columns and rafters—is designed using advanced CAD and structural analysis software to ensure:

- Maximum load-bearing strength

- Material optimization for reduced cost

- Customization based on span, height, and roof pitch

The primary framing provides the skeletal support needed to hold up the roof, sidewalls, and attached components securely.

2. Secondary Members

The secondary framing system supports the overall stability of the structure and helps distribute loads from the roofing and walls to the primary frame. These members include:

- Purlins: Horizontal beams supporting the roof sheets

- Girts: Horizontal beams attached to wall cladding

- Eave struts: Positioned at the roof and wall junction, providing support and shape

These components:

- Provide lateral support to prevent buckling of the primary frame

- Act as fixing points for roof and wall panels

- Improve the overall rigidity and durability of the structure

Made from lightweight yet strong cold-formed steel, secondary members are essential for structural balance and wind resistance.

3. Roofing and Cladding

Roof and wall panels in a PEB are made from high-quality materials like galvanized steel sheets, color-coated panels, or sandwich panels (with insulation cores like EPS or PU). These serve as the building’s envelope, protecting it from external elements.

Advantages of PEB roofing and cladding:

- Corrosion resistance due to protective coatings

- Thermal insulation (in the case of sandwich panels)

- Lightweight, reducing structural load

- Quick and easy installation, reducing construction time

These panels come in a variety of profiles, colors, and finishes, allowing both aesthetic and functional customization.

4. Bracing Systems

A PEB must be stable under dynamic forces like wind loads, seismic activity, and heavy machinery movement. Bracing systems are critical for maintaining this stability.

Types of bracing include:

- Cross bracing (X-bracing) – uses tension rods or cables to provide diagonal support

- Portal frames – moment-resisting frames used where cross bracing is not feasible

- Rod or angle bracing – for longitudinal and lateral support

Functions:

- Resist horizontal forces

- Maintain dimensional accuracy

- Prevent sway or lateral displacement

Bracing systems ensure the PEB maintains structural integrity under all operational conditions.

5. Accessories

PEBs are highly versatile and can be customized with a wide range of accessories to enhance functionality, comfort, and operational efficiency. These include:

- Skylights – for natural lighting

- Turbo ventilators and ridge vents – for airflow and temperature control

- Canopies and overhangs – for weather protection at entry points

- Mezzanine floors – for office space or storage within the building

- Rainwater gutters and downspouts – for drainage and water management

- Doors, windows, and louvers – for utility access and air circulation

These elements are pre-fabricated and installed during the erection process, ensuring smooth integration into the overall structure.

Advantages of PEB (Pre-Engineered Building)

✔ Faster Construction Time

One of the most significant advantages of Pre-Engineered Buildings is the drastically reduced construction time. PEBs are fabricated in a controlled factory environment using precision engineering tools and techniques. This means that components such as beams, columns, wall panels, and roofing sheets are pre-designed and pre-cut to exact specifications before arriving at the site.

Since the assembly process is streamlined and involves minimal on-site labor, PEBs can be erected up to 50% faster than conventional brick-and-mortar or concrete structures. This is especially beneficial for businesses with tight deadlines, time-sensitive expansions, or operations requiring rapid deployment.

✔ Cost-Effective

Cost-effectiveness is a hallmark of the PEB construction model. These structures save money in several ways:

- Reduced material waste thanks to precise prefabrication

- Lower labor costs due to faster assembly and reduced manpower needs

- Shorter construction timelines, which minimize overhead and financing costs

- Integrated design that avoids unnecessary complexity and rework

In addition, since PEBs are lighter than traditional buildings, they may reduce foundation load, leading to further cost savings in civil work. Over the entire project lifecycle, PEBs deliver substantial return on investment (ROI) for commercial and industrial users.

✔ High Strength-to-Weight Ratio

Steel, the core material in PEB systems, offers an exceptionally high strength-to-weight ratio. This means that even lightweight steel frames can support significant loads, enabling wide clear spans and multi-story construction without the bulk associated with concrete or brick.

This strength allows for:

- Large open spaces without internal columns (ideal for warehouses and showrooms)

- Enhanced resistance to environmental forces such as wind and seismic activity

- Reduction in structural dead load, which in turn lessens the foundation size and cost

By optimizing load-bearing capacity without adding excessive weight, PEBs provide safe, structurally sound solutions for diverse applications.

✔ Minimal Maintenance

PEBs require significantly less maintenance compared to traditional construction. Structural steel is:

- Corrosion-resistant when properly galvanized or coated

- Insect-proof, unlike wood structures which are prone to termite damage

- Fire-resistant, especially when treated with intumescent paints or fire-retardant coatings

Additionally, the metal roofing and wall cladding used in PEBs are designed for long-term durability, often with warranties of 15–25 years. Regular inspections and minor touch-ups are generally all that’s needed, making PEBs a low-maintenance investment over time.

✔ Eco-Friendly Construction

Sustainability is a growing concern in modern construction, and PEBs address this need effectively. These buildings are designed with the environment in mind:

- Reduced site disruption due to off-site fabrication

- Less construction waste, lowering landfill contributions

- Use of recyclable materials, particularly structural steel

- Opportunity to integrate green building features like solar panels, rainwater harvesting, and high-efficiency insulation

Moreover, when a PEB reaches the end of its lifecycle, most of its materials—especially the steel frame—can be recycled or reused, reducing its environmental footprint.

✔ Flexible Expansion

Business needs evolve, and buildings must be adaptable. PEBs are inherently modular and scalable, making them ideal for expansion:

- Horizontal expansion: Additional bays can be added seamlessly by extending the existing structure.

- Vertical expansion: Multi-story steel systems can be pre-designed to accommodate future upper floors.

- Customizable interiors: Movable partitions and reconfigurable layouts allow internal modifications without structural changes.

Whether your facility needs to grow by 20% or double in size, PEBs offer a cost-effective and time-saving pathway for future development.

Applications of PEB Structures

PEB systems are used across various sectors due to their adaptability and efficiency:

Industrial Sector

- Manufacturing units

- Warehouses

- Workshops

- Cold storage units

Commercial Sector

- Malls and showrooms

- Office buildings

- Retail stores

- Exhibition centers

Institutional and Infrastructure

- Schools and universities

- Airport terminals

- Sports complexes

- Railway stations

Residential Sector (Modern Adoption)

- Villas with steel frames

- Modular housing units

- Farmhouses and weekend homes

PEB vs Conventional Buildings

| Feature | PEB | Conventional Building |

| Speed | Fast (up to 50% quicker) | Slow |

| Cost | Predictable and optimized | Often exceeds budget |

| Customization | High | Medium |

| Material Waste | Minimal | High |

| Labor | Low | High |

| Structural Weight | Light | Heavy |

Why Choose PEB for Your Next Project?

Opting for a Pre-Engineered Building (PEB) system is a strategic decision for modern construction projects. Whether you’re building an industrial warehouse, commercial facility, institutional space, or storage unit, PEBs offer distinct advantages that deliver results beyond conventional construction. Here’s why choosing PEB is the smart move for your next build:

Precision Engineering

Pre-Engineered Buildings are developed using advanced computer-aided design (CAD) and structural analysis software, ensuring pinpoint accuracy and quality. Every component—be it beams, columns, or panels—is fabricated in a factory-controlled environment under stringent standards. This eliminates guesswork, reduces human error, and guarantees that the structure performs exactly as intended. Precision engineering also means your building meets both safety regulations and functional requirements without costly rework.

Time Efficiency

One of the biggest benefits of PEB construction is the significant reduction in project timelines. Since most components are prefabricated off-site, they can be assembled rapidly upon delivery to the construction site. Unlike traditional building methods that depend heavily on weather and manual labor, PEBs allow for year-round progress with fewer delays. For businesses, this translates into faster occupancy, quicker ROI, and earlier operational start-up.

Budget Control

In any construction project, cost overruns and hidden expenses are major concerns. PEB systems offer predictable budgeting through accurate design, minimal material waste, and reduced labor costs. Because the entire structure is pre-planned and fabricated before on-site work begins, clients benefit from clear pricing with minimal surprises. Additionally, faster construction leads to lower overhead and site management expenses—making PEBs a highly cost-efficient solution.

Long-Term Value

A PEB is not just quick to build—it’s also built to last. The use of high-quality steel components ensures long-term structural durability with minimal maintenance. PEBs are resistant to corrosion, termites, fire, and environmental wear, reducing lifetime repair costs. Moreover, these buildings are easily expandable and reconfigurable, offering future flexibility that extends their service life. Whether you plan to grow your business or adapt to changing operational needs, PEBs provide adaptability without starting from scratch.

Choosing a Pre-Engineered Building for your next project is an investment in speed, precision, affordability, and future-readiness. If you’re looking for a solution that combines engineering excellence with operational efficiency, PEBs deliver on every front.

Tesco Structure – Expert in PEB Construction

If you’re planning an industrial shed, warehouse, or commercial facility, Tesco Structure delivers end-to-end PEB solutions. From concept to installation, Tesco handles:

- Custom PEB designs

- Structural engineering

- Fabrication and material handling

- Onsite assembly and erection

- Post-construction support

With a proven track record in delivering durable, efficient, and scalable PEBs across sectors, Tesco is your trusted partner for modern steel construction.

Conclusion

A Pre-Engineered Building (PEB) is more than a construction technique—it’s a strategic approach to building faster, smarter, and more sustainably. Whether you’re expanding your factory, setting up a warehouse, or building a commercial complex, PEBs offer a future-ready solution.

By integrating precision, speed, and affordability, PEBs are redefining how we approach construction in today’s fast-moving world. If you want to optimize your building project, reduce risk, and ensure long-term performance, PEBs are the way forward.

Need help with your next Pre-Engineered Building project?

Get in touch with Tesco Structure today and experience the power of intelligent construction.